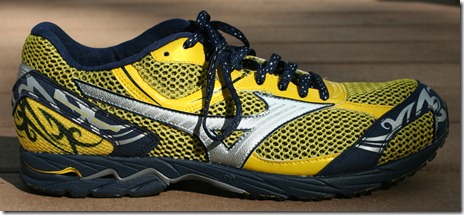

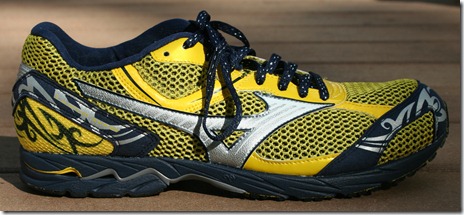

Of all of the 40+ shoes I have run in over the past 2+ years, the Mizuno Ronin 2 ranks right near the top in terms of comfort (along with the New Balance MT101 and a few others). The Ronin 2 is very roomy, and the forefoot is both wide and high volume (sadly, Mizuno reduced the forefoot width in the Ronin 3). The one problem with the shoe, however, is that it had a 9mm heel lift (23mm heel, 14mm forefoot). This exceeds my heel lift tolerance these days, and the shoe had been relegated to my closet quite awhile ago. Quite a shame, as the Ronin 2 is a very nice shoe…

Of all of the 40+ shoes I have run in over the past 2+ years, the Mizuno Ronin 2 ranks right near the top in terms of comfort (along with the New Balance MT101 and a few others). The Ronin 2 is very roomy, and the forefoot is both wide and high volume (sadly, Mizuno reduced the forefoot width in the Ronin 3). The one problem with the shoe, however, is that it had a 9mm heel lift (23mm heel, 14mm forefoot). This exceeds my heel lift tolerance these days, and the shoe had been relegated to my closet quite awhile ago. Quite a shame, as the Ronin 2 is a very nice shoe…

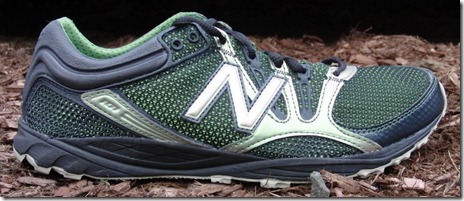

A few months ago, my friend Tuck from the Yelling Stop Blog offered to send me a pair of New Balance MT101 trail shoes that he had taken to a cobbler in order to have the sole leveled out. Tuck prefers to run in very minimal shoes like the Vibram Fivefingers, and he had not gotten much use out of the zero dropped MT101’s. Tuck’s cobbler did a fine job on the shoes, and I have been wearing them frequently this summer (including on a run/hike up the Flat Irons in Boulder last weekend!). Below are pictures that compare my standard pair or MT101’s (about 8mm drop) to Tuck’s zeroed MT101’s:

Unmodified New Balance MT101

Zero Dropped New Balance MT101 (from Tucker Goodrich)

Wearing the zeroed MT101’s around got me thinking – maybe I should take a few pairs of shoes to a local cobbler and have them zeroed off. The Mizuno Ronin’s were the first candidate that popped into my mind. Ever since I first looked at the Ronin 2, I had contemplated trying to cut down the heel. Because the sole under the heel is separated from that of the forefoot by the exposed plastic wave plate (see photo below), I figured that of any shoe, this one would be an easy hack job. Rather than go the professional route, maybe I could just do it myself? All I would have to do would be to shave the heel off just below the ridges of the silver wave plate (see photo below), and it would bring the Ronin to nearly zero drop.

Earlier today I finally got up the guts to make my first attempt at modifying the sole of a running shoe. I gathered the tools that I thought might come in handy (I’m quite happy that my wife wasn’t home when I did this…):

As it turns out, the hack saw and the metal file were all that I needed. I used the hack saw to cut the heel off in one piece:

Intact sole of Mizuno Wave Ronin 2

Mizuno Wave Ronin 2 with heel removed just below the wave plate

I then used the metal file to even and smooth off the exposed EVA. I also found that simply putting the shoe on my foot and rubbing the exposed heel back and forth on a patio brick did a nice job smoothing it out:

In all, I wound up taking about 8-9mm off the heel, and measurements with my digital calipers indicate that the shoe is now about 1mm drop from heel-toe (see before and after photos below).

Mizuno Wave Ronin 2 before heel removal

Mizuno Wave Ronin 2 after heel removal (about 1mm drop)

My main concern initially was that by removing so much of the heel, I would be able to feel the plastic wave plate under my foot. However, upon putting the shoes on they felt quite comfortable, very much like my zero dropped New Balance MT101’s. Haven’t had a chance to run in them yet, but I’m now very much looking forward to giving them a try. I could see this becoming a bit of a habit, just need to find some real cobbling tools!

Hi Pete

I’ve never had the guts to “deface” a shoe but maybe it’s time. Like you, i have a lot of shoes sitting in my closet (such as my ex-favourite pair, thewave musha) because of the heel drop. hmm, i know i have hacksaw in the garage somewhere.

Looks cool. Same deal here, have a bunch of shoes collecting dust in my closet since I went the minimalist route, might have to give it a try.

What did you use to glue it back on? Contact cement?

Ditto. Important info!

Didn’t glue the sole back on at all, just cut it of and left the exposed EVA. Figured I can put the outsole back on later if it turns out that I need it, but feels pretty good as is.

Sent from my iPad

Are you concerned that the exposed EVA will continue to wear down leading to a negative drop? I realize you don’t heelstrike, but if rubbing them against your patio smoothed them, it shouldn’t take much contact to wear them down to the wave plate. At least keep us updated concerning that matter.

That’s why I’m reserving the outsole portion. If it becomes an issue, I’ll just glue part of it back on :)

I did pretty much the same thing with my combat boots while in the Air Force. I spent 12hrs a day in them, usually on my feet, and I figured going from a pretty high heel to a low drop racing flat for my runs would probably not be good for my calf/achilles/plantar fascia. I just hacked off the entire extended heel part (definitely less tricky than it would be with most running shoes) and I had zero-drop combat boots!

You didn’t glue the outsole back on? I am a Marine and was thinking of doing the same to mine, but keeping the outsole.

It’s a work in progress – I have now glued the outsole back on one side, but need to finish the job on the other side.

Dear Pete,

I found a cobbler who did pretty much the same with my Wave Aero 8. It turned out that while running I could feel the wave plate pretty strong which stressed my calves. So I ditched them. However, the same cobbler zero dropped me a pair of Mizunos’ Wave Harrier 3, and I have to say I love them for muddy trails where the Trail Glove is not the proper choice.

Good Luck for your first run in the Ronin!

Manuel

CAn you offer more detail on how you measure the heel drop of a shoe? You mention the use of calipers, but presumably what matters is the drop on the inside, not the outside of the shoe. I’m intrigued by the idea of loitering the drop on some of my shoes but I’d like to measure it first.

I use digital outside or C-calipers. Just added a link to the ones that I use on the top left column of the blog. Very handy as they pinch the sole from above and below.

Thanks, but I don’t see the link. I assume you mean something like these: link to amazon.com…

Sorry, I took it down. That’s the one.

I have done this with a couple of my favorite shoes that I liked in all aspects other than the heel: Brooks Launch, Nike Free V2. I find that for my home cobbling an electric knife works really well, with the bread blade working better than the meat blade. I try not to do this around my wife though as she gets a little irritated. Happy cobbling!

I’ve been modifying shoes as well – although to accomodate my wide midfoot rather the heel drop. I have considering cutting down the heel a couple of my shoes but sticking the sole back to the midsole. Do you know of a good glue that would work well for rubber to EVA midsole?

One thing that is an issue hacking away at the heel won’t solve, in fact it’ll make it worse is the excessive toe spring found on some shoes. The MT101 is the worst shoe for toe spring in my collection, and this is without removing the heel. I really didn’t like the toe spring in my MT101’s – my toes just didn’t feel like they touched the ground unless going up steep hills. Considering that your toes are their for balance it’s pretty crazy that some shoes prevent your toes from coming close the ground till toe off.

If I were to attack my MT101’s the excessive heel, crazy toe spring and lack of lateral stability at the heel would be on my on my short list. Anyone heard of mods to shoes to address the toe spring and problems with lateral stability?

Lots of people on the Born to Run forum use Barge Cement to glue their various soles. Might be worth a try.

Having done this myself (and also not replacing the outsole), I can just advise to watch out for tile floors with any moisture!

This is definitely the kind of thing you want to do alone, you can almost hear your wife busting your chops from here, asking questions like “Why would you do that, how much did you pay to cut them up, etc.” To say nothing of the failed/attempted home improvement projects of the past that are continually mentinoed . . . or am I alone? :)

Great post. I have a pair of Ronin’s that I just haven’t been able to work into my routine. Any suggestions on approaching shoe “deconstruction” as you seem to have digitally mastered.

I was just winging it. Grabbed the hacksaw and went at it, turned out pretty well. Just bought a Dremel which may help with evening the cut sole out a bit. Either that or I’ll wind up melting the foam from friction :)

Another method is the handy old belt sander. Just flip it over on your bench, and go at it! And for calipers in our store we use an Irwin adjustable clamp that we’ve marked with mm marks! Very easy to measure drops on shoes with these.

Kyle Roberts, C. Ped., Revolution Natural Running

Milwaukee, WI

I’ve zero dropped a pair of NB 100s, then 101s, and Brooks Green Silences. Using a hack saw and kitchen knife, I removed a predetermined wedge of midsole from the heel to the forefoot (to about the natural metatarsal-phalangeal flex point), and then glued the two sides of midsole back together with Household Goop (that’s the brand name). I was skeptical that the adhesive would hold, but a couple of ultramarathons and 300+ miles later I can’t detect any loss of structural integrity. Maybe the trick was gluing midsole to midsole, not gluing rubber outsole to EVA.

I also have very wide feet (my 4ht and 5th toes ripped through Merrell Trail Gloves and Altra Instincts in two weeks), so I have to do “shoe surgery” on the toebox of all my shoes to increase their width. I make an incision on the distal-lateral toebox, approximately where my 4th and 5th toes rub, and sew in an elliptical patch of polyester or nylon fabric that effectively increases the volume and width of the toebox fabric. My lateral toes hang over the midsole, but one adapts to it very quickly, and it allows me to use racing flats that otherwise would not fit my foot at all. For example, the NB 101 is very narrow out of the box, but after removing all the excess overlays around the toes and metatarsal heads before sewing in a patch, it’s much roomier. I’m now at the point where I see “anatomical last” and just laugh: the shoe doesn’t look remotely like my foot, but it’s a starting point, and with a little work I can make a lot of racing flats work well for me.

This is Awesome! Exactly what I have been looking for! Since then have how has the running been?? I need a shoe with zero-drop but more support I run D1 and they always give us these shoes with so much heel drop…is kills me. Would you say this is applicable to basically any running shoe? Lastly, do you notice a huge difference from the modifications to the manufactured “zero-drops”

Wrote this several years ago so can’t recall much about them. Whether or not hacking the shoe will work really depends on the construction. Nowadays there are so many good options out there that this type of job isn’t really necessary – we’ve come a long way in a few years,

Sent from my iPad

I get loads of shoes with too much heel, cant sell them for much or trade em anywhere…had to resort to this sadly. I’ve bought some zero drops but they’re a bit expensive.

Have you tried Ebay? I sometimes can get near retail price for mildly used shoes.

—-

Pete Larson’s Web Links:

-My book: Tread Lightly: link to ow.ly

-Blog: https://runblogger.com

-Twitter: link to twitter.com

-Facebook Page: link to facebook.com…

-Discussion Forum: https://runblogger.com/forum

does a hacksaw give a clean cut? or wil it leave the sole grainy? I bought some adidas revenergy boost and they really screwed up my running. I cant afford another pair of shoes after paying $150, and need to modify these.

It’s not an ideal solution, but worked ok. You might be able to take them to a cobbler and have them do the job for you.

so would you say a long knife blade thats very sharp would make a cleaner cut? Something like a high quality kitchen or bread knife? Or maybe even taking it to a woodshop and ask them to cut it withe their bandsaw ?

I cut the soles off an old pair of adidas climacools with a 3.5″ pocket knife, but it was hard to get a totally level plain.

Thanks